Diamond Wire Supplier in South Africa – Rapid Products

Unleash Precision, Unleash Power: Rapid Products’ Diamond Wire – Redefining Cutting Excellence.

Need a diamond wire supplier in South Africa for your concrete cutting needs? In the realm of diamond cutting and drilling, precision and reliability are non-negotiable. Whether it’s sculpting granite in quarries or shaping marble in construction, the tools employed must meet the highest standards of performance. Rapid Products, a pioneering force in the industry, introduces its groundbreaking Diamond Wire solutions, engineered to exceed expectations in the most demanding applications.

NEED A QUOTE FOR HIGH QUALITY PRODUCTS?

Why choose Rapid Products as your Diamond Wire Supplier in South Africa

- Cutting-Edge Technology

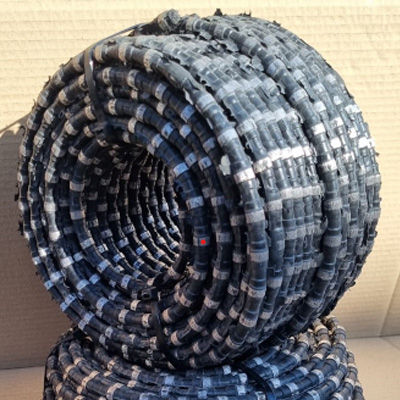

Rapid Products’ Diamond Wire epitomises innovation, representing a seamless fusion of cutting-edge technology and meticulous craftsmanship. Crafted from a continuous strand of meticulously selected materials, including plasticised, rubberised, or spring-mounted steel wire, our Diamond Wire is fortified with diamond-impregnated beads. This strategic combination ensures unparalleled cutting speed and precision, even in the harshest conditions and toughest materials.

- Versatile Applications

Versatility is at the core of Rapid Products’ Diamond Wire offerings. Whether it’s horisontal or vertical cuts, our wire solutions excel across a diverse spectrum of applications. From dimension stone quarries to cutting plants equipped with stationary and multi-wire machines, our Diamond Wire delivers consistently exceptional results. Moreover, our wire solutions cater to both wet and dry applications, offering unparalleled adaptability to varying work environments.

- Unrivalled Performance

When it comes to performance, Rapid Products’ Diamond Wire sets a new benchmark. Boasting a range of wire sizes tailored to specific requirements, our offerings ensure optimal efficiency and productivity. With bead configurations optimised for different applications, our wire solutions guarantee superior cutting performance across materials such as granite, marble, sandstone, slate, onyx, concrete, and reinforced concrete.

| Wire Size | Beads per Meter |

| 8.5mm | 40 (stationary) |

| 10.4mm | 30 (stationary) |

| 10.4mm | 30 (quarry) |

| 11.4mm | 35 (quarry) |

| 11.4mm | 40 (quarry) |

For specialised demolition wire applications, Rapid Products offers additional customisation, featuring the required wire and springs at an added cost of R28 per meter. This underscores our commitment to providing tailored solutions that meet the unique needs of our clientele. Call the trusted diamond wire supplier in South Africa to get quality diamond drilling and cutting products for your project.

Rapid Products offers high quality products

About Rapid Products

Mission:

To develop lasting client relationships by providing exceptional service and products.

Vision:

To be the best supplier in Southern Africa in our industry.

Core Values:

Quality: service and products we are proud to stand behind.

Passion: Enthusiasm, desire, to and commitment to succeed.

Honesty, integrity and professionalism.

Our objectives:

To always achieve our desired results

To search for new and improved products.

To be a valued business partner for our customers and suppliers.

NEED A QUOTE FOR HIGH QUALITY PRODUCTS?

Diamond Wire for Concrete Coring and Cutting: Versatile Solutions for Precision Work

Diamond wire technology has revolutionised the concrete coring and cutting industry, offering unparalleled precision, efficiency, and versatility in a wide range of applications. Here’s how diamond wire is utilised and its advantages in concrete coring and cutting:

- Precise Coring: Diamond wire provides precise coring solutions for concrete structures of varying thicknesses. Whether it’s creating openings for pipes, HVAC installations, or electrical conduits, diamond wire ensures clean and accurate cuts without causing unnecessary damage to surrounding areas.

- Efficient Slab Cutting: When it comes to slab cutting, diamond wire excels in efficiency and speed. From highway pavements to bridge decks, diamond wire can effortlessly slice through concrete slabs of any thickness with minimal disruption and maximum precision. This efficiency minimises project downtime and reduces labour costs.

- Complex Shapes and Curves: Unlike traditional cutting methods, diamond wire offers the flexibility to cut concrete into complex shapes and curves with ease. This capability is particularly useful in architectural and landscaping projects where intricate designs and patterns are desired.

- Reduced Vibration and Noise: Diamond wire cutting generates minimal vibration and noise compared to conventional methods such as saw cutting or jackhammering. This makes it ideal for use in urban areas, residential neighbourhoods, and sensitive environments where noise and disturbance must be minimised.

- Increased Safety: With its precise cutting action and minimal kickback, diamond wire enhances safety for both operators and surrounding personnel. The reduced risk of accidents and injuries makes diamond wire cutting a preferred choice for high-risk environments such as construction sites and industrial facilities.

- Minimal Dust Generation: Diamond wire cutting produces significantly less dust compared to traditional cutting methods, resulting in a cleaner and safer work environment. This is especially beneficial in indoor applications where dust control is essential for worker health and environmental compliance.

- Cost-Effective Solution: While diamond wire cutting may have higher upfront costs, its speed, precision, and efficiency translate into long-term cost savings. Reduced labor costs, minimal material waste, and shorter project timelines contribute to a more economical overall solution.

In conclusion, diamond wire technology has emerged as a game-changer in the realm of concrete coring and cutting, offering unmatched precision, efficiency, and safety. Whether it’s coring, slab cutting, or shaping complex structures, diamond wire provides a versatile and cost-effective solution for a wide range of applications in the construction and civil engineering industries.

Before & After

Call Rapid Products to order your Diamond Wire from the leading supplier in South Africa

Innovation, precision, and reliability are the cornerstones of Rapid Products’ Diamond Wire solutions. With a relentless focus on pushing the boundaries of possibility, we continue to redefine industry standards and empower our customers to achieve unparalleled success. Experience the future of cutting and drilling with Rapid Products’ Diamond Wire – where precision meets perfection.

Frequently Asked Questions About Diamond Wire by Rapid Products

Diamond Wire is a continuous strand of steel wire embedded with diamond-impregnated beads. It works by rotating around a cutting surface, effectively sawing through hard materials like granite, marble, and concrete with precision and efficiency.

Diamond Wire offers several advantages, including faster cutting speeds, reduced material waste, improved precision, and the ability to cut through a wider range of materials. Additionally, it minimises the need for secondary processing and results in smoother finishes.

Diamond Wire is versatile and can be used for various applications, including dimension stone quarrying, construction, demolition, and manufacturing. It’s ideal for horisontal and vertical cuts in materials such as granite, marble, sandstone, slate, onyx, concrete, and reinforced concrete.

Yes, Rapid Products provides Diamond Wire in various sizes and bead configurations to suit different cutting requirements. Our range includes wire sizes ranging from 8.5mm to 11.4mm, with beads per meter tailored for stationary cutting, quarrying, and demolition applications.

Absolutely. Rapid Products’ Diamond Wire is designed to excel in both wet and dry cutting environments. Whether you’re working in a water-rich quarry or a dry construction site, our Diamond Wire solutions ensure optimal performance and longevity.

Diamond Wire is highly durable, thanks to the abrasion-resistant diamond beads embedded within the wire. Its lifespan depends on various factors, including the type of material being cut, cutting conditions, and maintenance practices. With proper care and usage, Rapid Products’ Diamond Wire offers extended service life and reliability.

Yes, Rapid Products provides customisation options to meet specific customer requirements. Whether it’s adapting wire size, bead configuration, or incorporating specialised features for unique applications, our team works closely with clients to deliver tailored solutions that optimise cutting efficiency and performance.

NEED A QUOTE FOR HIGH QUALITY PRODUCTS?

Safety Measures

- Personal Protective Equipment (PPE): Prioritise the use of appropriate PPE, including safety glasses, gloves, hearing protection, and steel-toed boots, to safeguard against potential hazards such as flying debris, noise, and cuts.

- Equipment Inspection: Conduct thorough inspections of Diamond Wire cutting equipment before each use to ensure all components are in proper working condition. Check for loose bolts, damaged wires, and malfunctioning components, and address any issues promptly to mitigate safety risks.

- Hazard Identification: Identify potential hazards in the work area, such as uneven terrain, overhead obstructions, and electrical hazards, and implement measures to mitigate risks. Use barricades, signage, and warning lights to alert others to the presence of Diamond Wire cutting operations.

- Safe Operating Procedures: Establish and communicate clear and comprehensive operating procedures for Diamond Wire cutting activities, including startup and shutdown protocols, emergency response plans, and communication protocols among team members.

- Training and Certification: Ensure operators receive thorough training and certification in the safe operation of Diamond Wire cutting equipment. Provide ongoing training opportunities to reinforce safety protocols, equipment maintenance, and hazard awareness.

- Emergency Preparedness: Prepare for emergencies by maintaining first aid kits, fire extinguishers, and emergency communication devices onsite. Develop and practice emergency response procedures, including evacuation routes and protocols for addressing injuries or equipment malfunctions.

- Environmental Considerations: Consider environmental factors such as weather conditions, ventilation requirements, and potential impacts on surrounding ecosystems when planning Diamond Wire cutting operations. Implement measures to minimise environmental risks and comply with regulatory requirements.

- Continuous Improvement: Foster a culture of continuous improvement by soliciting feedback from operators, conducting regular safety audits, and implementing corrective actions to address safety concerns and enhance overall safety performance.

Prioritising safety measures and best practices when using Diamond Wire cutting equipment is essential to protect workers, mitigate risks, and ensure a safe and productive work environment. By implementing comprehensive safety protocols and fostering a culture of safety, organisations can minimise accidents, injuries, and downtime associated with Diamond Wire cutting operations.Top of Form

Maintenance and Care of your Diamond Wire

- Regular Cleaning: Implementing a routine cleaning schedule to remove debris, dirt, and cutting residues from the Diamond Wire helps prevent buildup and maintain cutting performance.

- Proper Tensioning: Ensuring the Diamond Wire is properly tensioned during operation is essential for optimal cutting results and prolonging its lifespan. Regularly check and adjust tension as needed to avoid overloading or slackening of the wire.

- Appropriate Lubrication: Applying lubricants or coolants during cutting operations, particularly in wet cutting environments, helps reduce friction, dissipate heat, and extend the life of the Diamond Wire. Choose lubricants compatible with the material being cut and the cutting conditions.

- Inspecting for Damage: Conducting regular inspections of the Diamond Wire for signs of wear, damage, or fatigue is crucial for early detection and preventive maintenance. Replace worn or damaged sections promptly to prevent further deterioration and ensure consistent cutting performance.

- Storage Practices: When not in use, store Diamond Wire coils in a dry, clean, and climate-controlled environment to prevent corrosion, rusting, or contamination. Proper storage helps preserve the integrity of the wire and extends its usable lifespan.

- Handling with Care: Exercise caution when handling Diamond Wire coils to avoid kinks, bends, or other physical damage that could compromise its structural integrity. Handle and transport the wire with care to prevent accidental damage during storage or installation.

- Documentation and Record-Keeping: Maintain detailed records of maintenance activities, including cleaning schedules, tension adjustments, inspections, and replacements. Documentation helps track the history of the Diamond Wire and facilitates proactive maintenance planning.

By adhering to these maintenance and care practices, users can maximise the longevity and performance of Diamond Wire, ensuring consistent cutting efficiency and minimising downtime due to premature wear or damage.

Why Choose Rapid Products as Your Diamond Wire Supplier in South Africa

- Unrivaled Quality: Rapid Products is committed to delivering diamond wire of the highest quality, meticulously crafted to meet the rigorous demands of the industry. Our dedication to quality ensures consistent cutting performance and reliability in every application.

- Versatile Solutions: With a wide selection of diamond wire sizes and configurations, Rapid Products offers versatile solutions to suit diverse cutting requirements. Whether for stationary cutting, quarrying, or demolition applications, our diamond wire delivers exceptional results across various materials.

- Innovative Technology: At Rapid Products, we leverage cutting-edge technology and continuous innovation to push the boundaries of diamond wire performance. Our solutions are engineered to maximise cutting speed, precision, and efficiency, setting new standards of excellence in the industry.

- Exceptional Durability: Built to withstand the toughest conditions and prolonged use, Rapid Products’ diamond wire is highly durable and abrasion-resistant. Our wire solutions offer extended service life and consistent cutting performance, minimising downtime and maximising productivity.

- Customer-Centric Approach: At the heart of Rapid Products’ business philosophy is a commitment to customer satisfaction. We prioritise customer needs and preferences, offering tailored solutions, personalised support, and responsive service to ensure a seamless experience from inquiry to delivery.

- Proven Track Record: With years of experience and a proven track record of success, Rapid Products is a trusted name in the diamond wire industry. Our satisfied customers attest to the quality, reliability, and performance of our products, making us the supplier of choice for diamond wire solutions in South Africa.

When you choose Rapid Products as your diamond wire supplier in South Africa, you’re not just investing in cutting-edge technology – you’re investing in a partnership built on quality, innovation, and unwavering commitment to your success. Experience the difference with Rapid Products and unlock the full potential of your cutting and drilling operations.Top of Form

Whether you’re tackling tough concrete or intricate precision work, Rapid Products stands as your premier Diamond Wire supplier in South Africa. With our commitment to quality, innovation, and customer satisfaction, we provide the cutting-edge solutions you need to drill with confidence and precision. Elevate your concrete coring game with Rapid Products today and experience the difference firsthand.

Related information: